LPCVD Systems

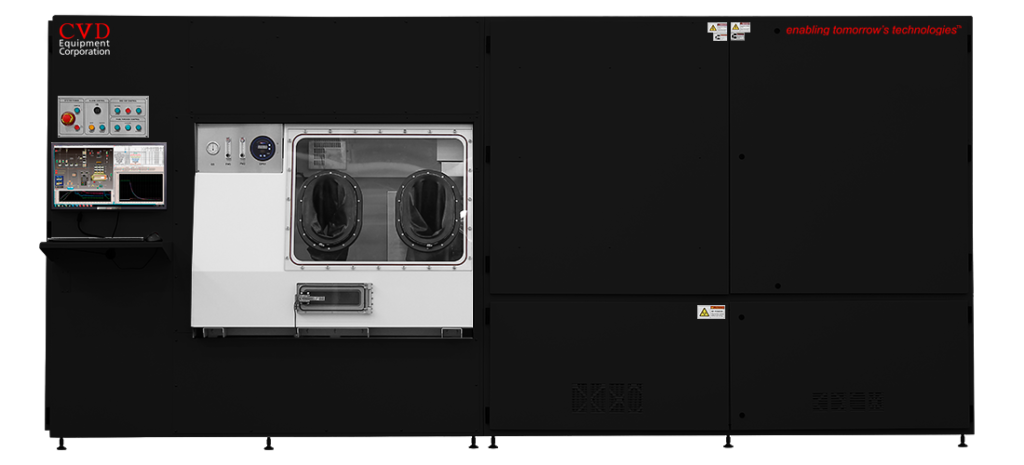

Low Pressure CVD (LPCVD) Systems

Our LPCVD systems can uniformly deposit many thin film materials, including wide bandgap semiconductors, silicon carbide (SiC), nitrides, oxides, polysilicon, transparent conductive oxides (TCOs), Si/SiGe epitaxial films, metallic and ceramic films, etc. The LPCVD systems are also used for nanomaterials synthesis including carbon nanotubes, graphene, semiconducting nanowires, and 2D crystals including boron nitride and transitional metal dichalcogenides (TMDs). LPCVD coatings typically exhibit excellent uniformity, high purity, and good step coverage.

We apply different vacuum system technologies depending on the requirements of the process. Vacuum systems are selected based on the types of chemistries involved and process pressure requirements. Our vacuum system solutions are designed to be low maintenance, robust, and reliable. Vacuum systems are integrated into a central control and safety system.

LPCVD SYSTEM FEATURES & OPTIONS

Processing of wafers up to 300 mm in diameter

Operational temperatures from 100 °C to 1100 °C with resistance heating, or > 1400 °C with induction heating

CVDWinPrC™ system control software for real-time process control, data logging, and recipe editing

Closed tube processing for a high purity and reproducible environment resulting in increased production yields

Moving furnace elements for fast heat-up and cool-down, and to ensure the proper process atmosphere exists prior to processing

Cantilever loading system for automatic noncontact loading of the wafer boat for minimal particle generation

Cascade temperature control using external (furnace) and internal (process) thermocouples for real-time continuous in situ control of temperature profiles

Better than 0.5 °C flat temperature zone up to 48″ in length

Independent computer control of each process tube

Multi-chamber cluster systems available

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”