Battery Materials/Energy Storage

Energy Storage and Battery Materials Development

Chemical Vapor Deposition PowderCoat Technologies to enhance material performance, provide higher energy density and efficiency than previous generation battery materials alone, enabling faster charging times and expanded EV range.

The Promise of Delivering a More Sustainable Future with Advanced Battery Materials for Electric Vehicles

Decarbonization requires the electrification of the entire energy supply chain. With reliance on cleaner, renewable power sources for the electrification of our transportation systems, broad adoption of electric vehicles (EVs) can significantly reduce the carbon released into the atmosphere. Researchers and industry need to scale technologies that will improve EV innovation, meet the demand for higher performance and increase battery lifespan without being cost-prohibitive to adapt to the marketplace.

Rising Demand for High-Energy-Density Batteries

In recent years, electric cars have evolved at an unprecedented rate as consumer preferences have shifted towards vehicles using sustainable energy sources. With the rising demand for hybrid EVs, plug-in hybrid EVs and battery powered EVs, the automotive industry is driving the demand for manufacturers to improve battery technologies to increase driving range and reduce charging times.

Advanced Materials for EV Batteries

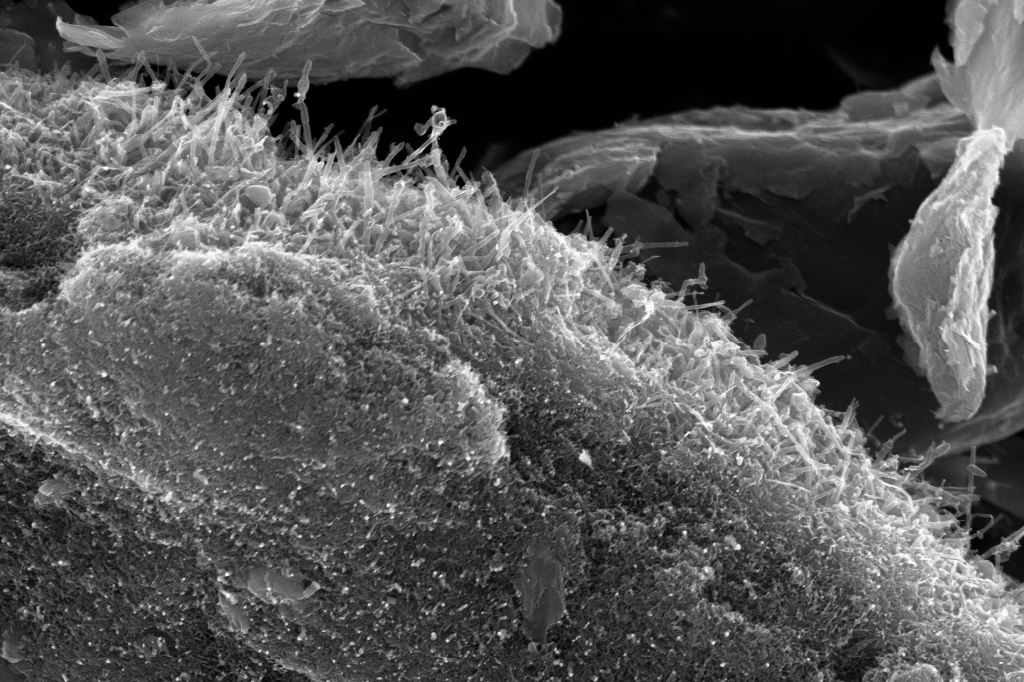

The current technology trend is to enhance the electrical performance of the existing graphite anode material with advanced nanomaterials in the form of coatings or nanowires, to supercharge the graphite anode in lithium-ion batteries. Silicon, for example, can store approximately ten times the amount of energy than graphite alone. Infusing silicon nanowires onto the surface of the graphite powder substrate increases silicon’s accessibility to lithium ions, helping to eliminate expansion and stability issues, and further increases energy density. By storing more energy per unit volume, these advanced battery materials have promising industrial applications.

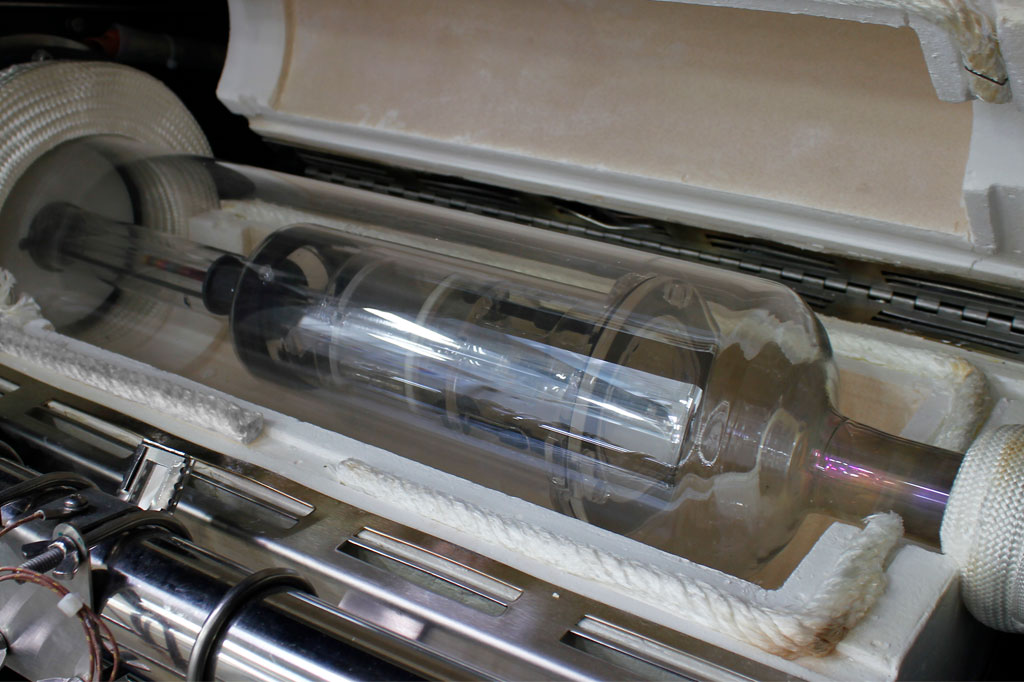

CVDE’s Industrial PowderCoat Process Equipment for Advanced Anode Materials

As performance improvements to lithium-ion battery material development are moving from research and development to production, CVDE is focused on supplying process equipment to manufacturers with systems that coat EV-grade graphite with conductive carbon additives, carbon nanotubes (CNTs), silicon-carbon composites, silicon, silicon nanowires (SiNWs) and other advanced nanotechnology materials for improving power and energy density, while maintaining the excellent cycling stability of graphite.

CVDE’s PowderCoat Furnaces

CVD Equipment’s chemical vapor deposition technology makes it possible to deposit a wide variety of materials such as silicon, carbon, metals, oxides, etc., onto various powder substrates from sub-micron to hundreds of microns in size and can functionalize the surface with coating thickness ranging from a few nanometers to tens of microns for enhanced material performance. Multi-reactors and robust process controls are an essential key to our system build for robust continuous coating and infiltration. Rapid cooldown features result in high throughput processing for high-volume manufacturing. Supporting both, industry, and researchers worldwide to find next generation novel battery material technologies.

Improved Batteries for EVs

Materials processed through CVDE’s furnaces result in enhanced material performance, greater energy density, and the capability to charge faster. An EV with battery materials made from CVDE’s engineered systems delivers the material performance that will build tomorrow’s high-powered electric future.

Powders & Advanced Materials

Customized and standard solutions for demanding temperature processes,

CVDE is your best choice

for scaling from R&D to production

for innovative process solutions for commercial markets, government, and university research and development

for testing, simulation, and optimization

for trusted collaboration

for high quality systems and advanced materials

Industrial Manufacturing

PowderCoat 1104™ Features & Benefits:

High Volume Powder Infiltration & Uniform Coating

Multi-Reactor Chambers for Parallel or Sequential Processing

Low-Pressure CVD

5 Zone Resistance Furnace Heating Systems

Customizable Inconel Chamber

Rotating Tumbler for Uniform Mixing

Robust Production System with Enhanced Process Controls

– Temperature Control +/- 0.5°C

– Pressure Control +/- 1%

Rapid Cool Down

Powered by CVDWinPrC™

MES Compatible

Research & Development

PowderCoat 300™ Features & Benefits:

Powder Infiltration & Uniform Coating

Single Reactor Chamber Processing

Low-Pressure CVD

3 Zone Resistance Furnace Heating Systems

Customizable Quartzware Chamber

Rotating Tumbler for Uniform Mixing

Robust Production System with Enhanced Process Controls

– Temperature Control +/- 0.5°C

– Pressure Control +/- 1%

Rapid Cool Down

Glovebox for Unloading Sample Under Inert Ambient Conditions

Powered by CVDWinPrC™

EV-Grade Graphite + Precursor Silane Gas

CVD Equipment’s PowderCoat 1104™ Processing System

Silicon Nanowire Infused Graphite

Industrial Powder Coating for Battery Material

Using our state-of-the-art CVD Processing System designed to generate high-performance nanomaterials for EV battery applications: At an order of magnitude one billionth of a meter, silicon can be infused at the surface of each graphite particle in the presence of silane gas under the proper thermodynamic and kinetic conditions, allowing for these electrical nanowires to be infused or in a way, plugged into the graphite, much like a cord is plugged into an electrical outlet. Once electrically charged, these nanowires remain pliant and do not crack in this state. As a result, this can avoid the inefficiencies of trapping silicon inside. With hundreds of thousands of wires on each graphite particle, more potential energy is gained by silicon, and the energy density of the anode becomes greater.

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”