Medical

Medical Device Coatings for the Healthcare Industry

Medical devices often require functional coatings for performance and bio-compatibility. Since these devices typically have complex geometries with tight tolerances, a coating technology needs to be applied that can uniformly coat the surface. Chemical vapor deposition is the best choice in many cases since it also generates dense, high-purity, thin films with a high degree of material composition control.

CVD Equipment Production Systems Used to Process Materials for the Medical Industry

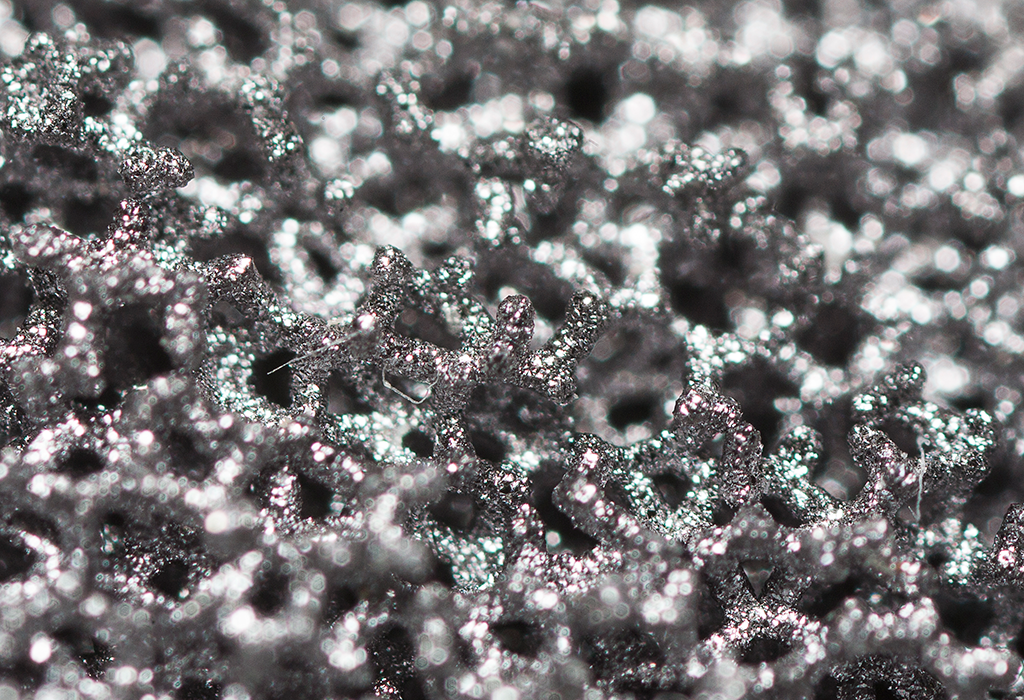

Our systems are routinely designed to meet the strict requirements of the FDA. Repeatability, reliability, traceability, and performance all have to be maintained to high standards. Ta metal offers benefits that can enhance preexisting implant systems. Worth noting, is that given the high density of Ta, and the difficulty of machining Ta using traditional means, whole Ta implants are impractical. However, CVD processing can uniquely enable the use of Ta for implants, without compromising the novelty of the manufacturer’s orthopedic system. Ta can be coated evenly onto a complex 3D shape by CVD. This coating may serve as a mechanical sealant to protect roughening beads/particles from disintegrating over time.

Benefits of Tantalum for Orthopedics Implants

Excellent corrosion resistance

Good wear resistance for joints. For instance, Ta coated on CoCrMo has demonstrated better characteristics than DLC coated on CoCrMo.a

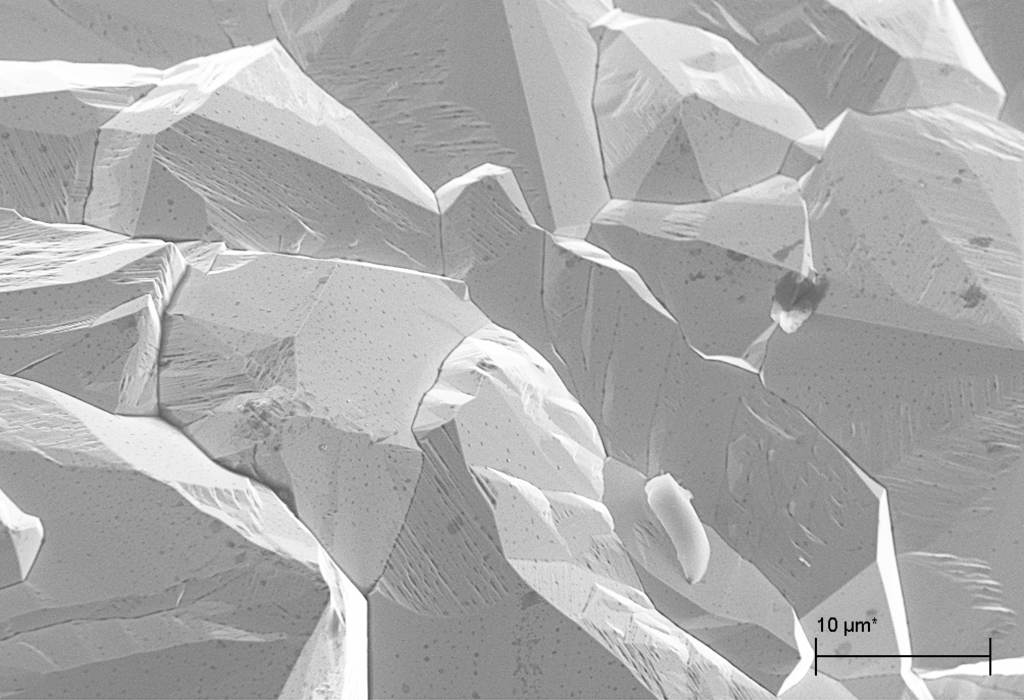

Alpha (α)-Ta can be obtained by CVD with the appropriate recipe, perhaps directly, or obtained irreversibly by post-deposition annealing of the deposited β-Ta.b α-Ta is known for having noteworthy ductility.c Meanwhile, implants coated by Ti-thermal spray have been shown to suffer from a ~30% loss of implant coverage during ex-situ impact testing.d The ductility of α-Ta could prove to be an improvement upon long-term implant durability as compared with a coating of the typical thermal-sprayed Ti.

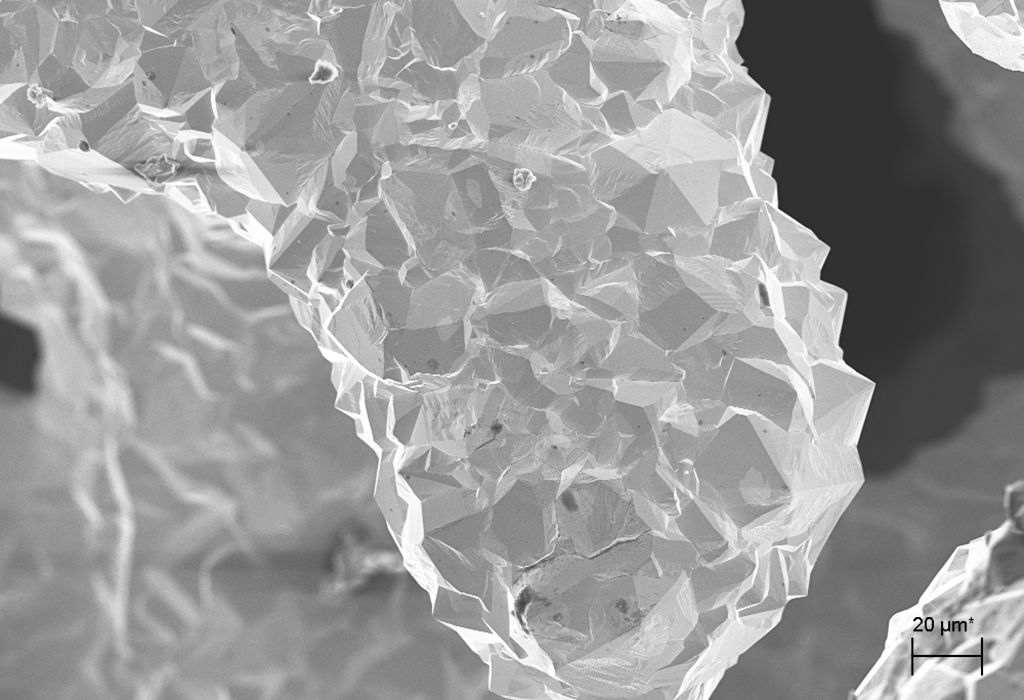

Observed cell proliferation on the various surfaces (where greater is better): Ta > HA > Tie,f

Ta features low ion release, and as such, may serve as a good chemical ‘sealant’ when uniformly coated onto metal alloys such as CoCrMo.g Co and Cr ions, are not bioinert, and have been shown to elicit an unwanted biological response.h

Initial cell attachment onto tantalum has been observed to be comparable to that of hydroxyapatite (HA).f However, there are concerns about the long-term durability of HA-coated implants, as HA is known to exhibit cracking and delamination, and undergoes a phase change to its lesser preferred amorphous phase.i

Ta biologically bonds to the bone.a,e,f

Better cellular adhesion than Ti – Tantalum has a higher surface energy than titanium, enhancing cell-material interaction on Ta.e

A statistically significant, higher density of proliferated cells has been observed on the surface of Ta as compared with a similarly pretreated Ti surface, also having a similar morphology.e

(a)Sci. Technol. Adv. Mater., 2014, 15 (1), 014402 (b)Inorg. Mater., 2017, 53 (10), 1064-1068 (c)Surf. Coat. Technol., 2004, 177–178 (30), 44–51 (d)Spine J., 2018, 18 (5), 857–865 (e)Acta Biomater., 2010, 6 (8), 3349–3359 (f)JOM, 2010, 62 (7), 61-64 (g)Mater. Sci. and Eng. C, 2012, 32 (4), 887–895 (h)J. Orthop. Res., 2013, 31 (9) 1484-1491 (i)Biomaterials, 1996, 17 (5), 537-544

Chemical Vapor Deposition Tantalum Processing

The Process

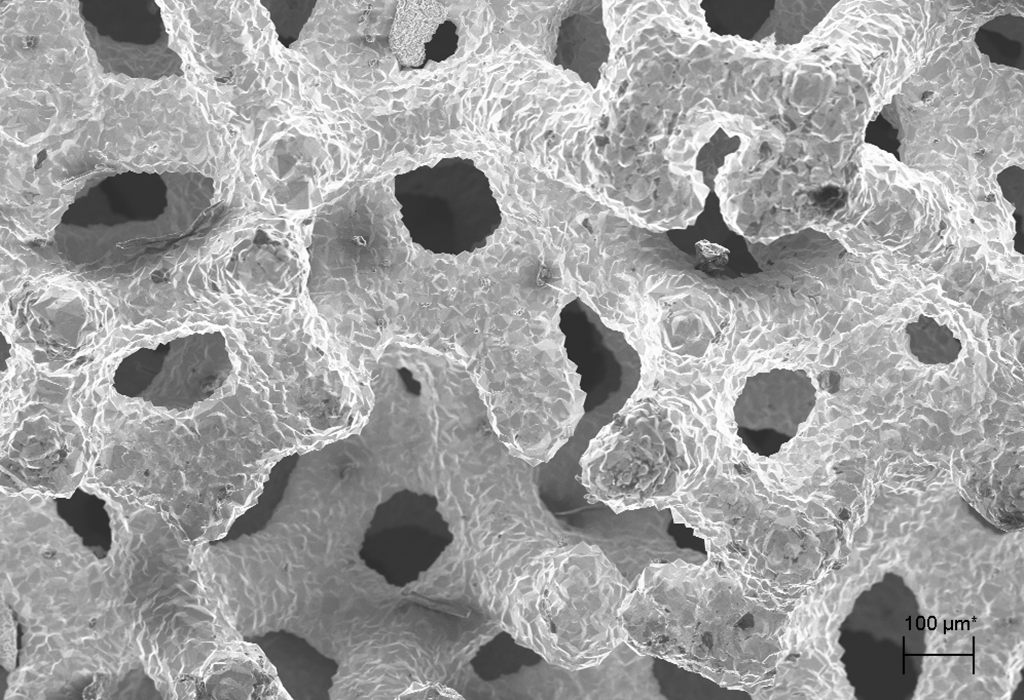

Chemical vapor infiltration (CVI) is a chemical vapor deposition (CVD) process that is performed at low pressures to allow for coating the internal surfaces of porous materials having complex shapes and geometries. Using heat and low pressure, precursor vapors penetrate the pores or fibers of the material and deposit to form a conformal coating on the internal surfaces.

CVI System Features & Options

Dual or multi-chamber configuration for improved productivity

Substrate temperatures 800 to 1200 degrees Celsius

High Temperature, RF Induction Heating up to 2500°C

Cascade temperature control using external (furnace) and internal (process) thermocouples for real-time continuous in-situ control of temperature profiles

CVDWinPrC™ system control software for real-time process control, data logging, and recipe editing

CVI Brochure

Advanced process tools for coating the internal surfaces of porous/fibrous materials

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”