Carbon+™ Systems

Advanced Tools for Producing Carbon Nanomaterials and Carbon Composites

Our FirstNano CARBON+™ family of systems is engineered to produce high-quality carbon nanomaterials and carbon composite structures for use in many applications. Carbon nanotubes and graphene exhibit extraordinary mechanical, electrical, and thermal properties. Our proven technology can grow these nanostructures and composites over a wide range of flow, temperature, and pressure conditions to meet and exceed the performance requirements of our customers. CVDE continues to advance the state-of-the-art in nanomaterial synthesis and production as part of its ongoing strategy of enabling tomorrow’s technologies™.

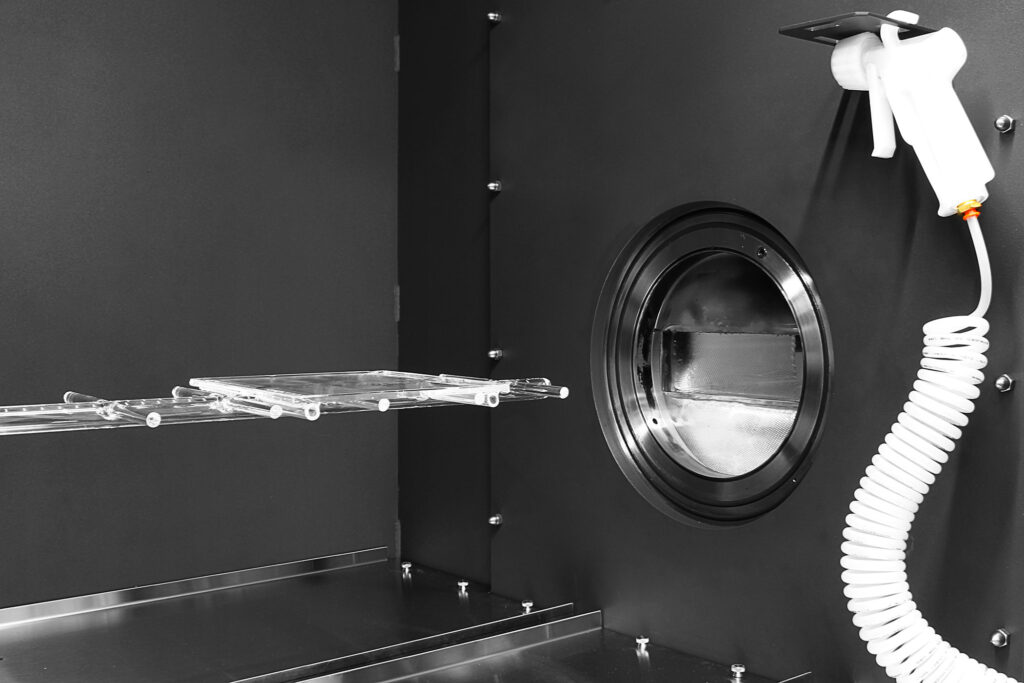

The Carbon+ systems include precursor gas and vapor control, CVD processing, and exhaust byproduct management in an integrated package. Our control systems use PLC logic and CVDWinPrC™ control software for recipe writing, data logging, and HMI control.

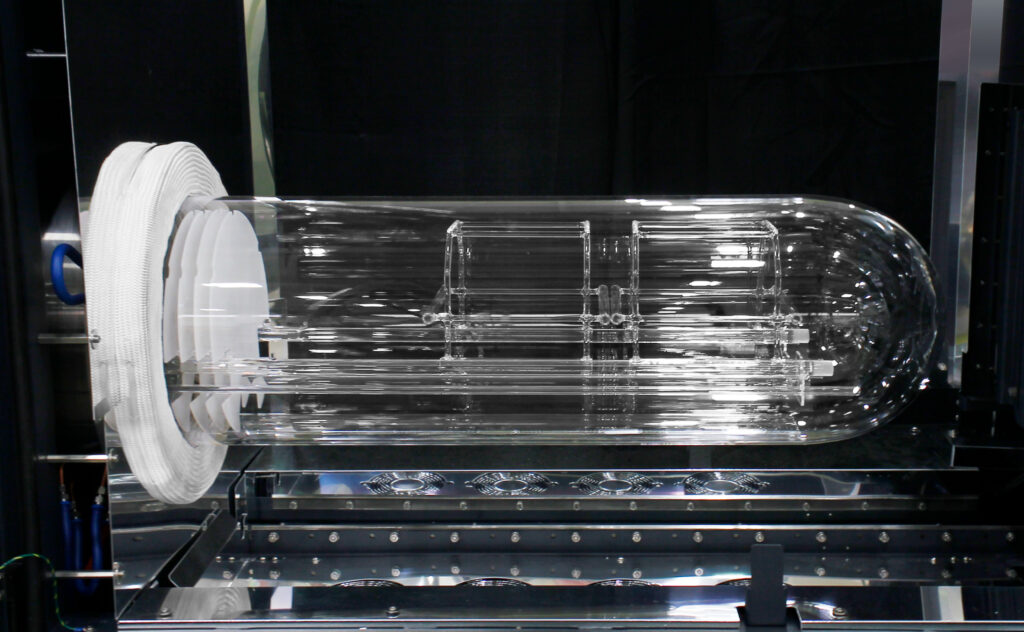

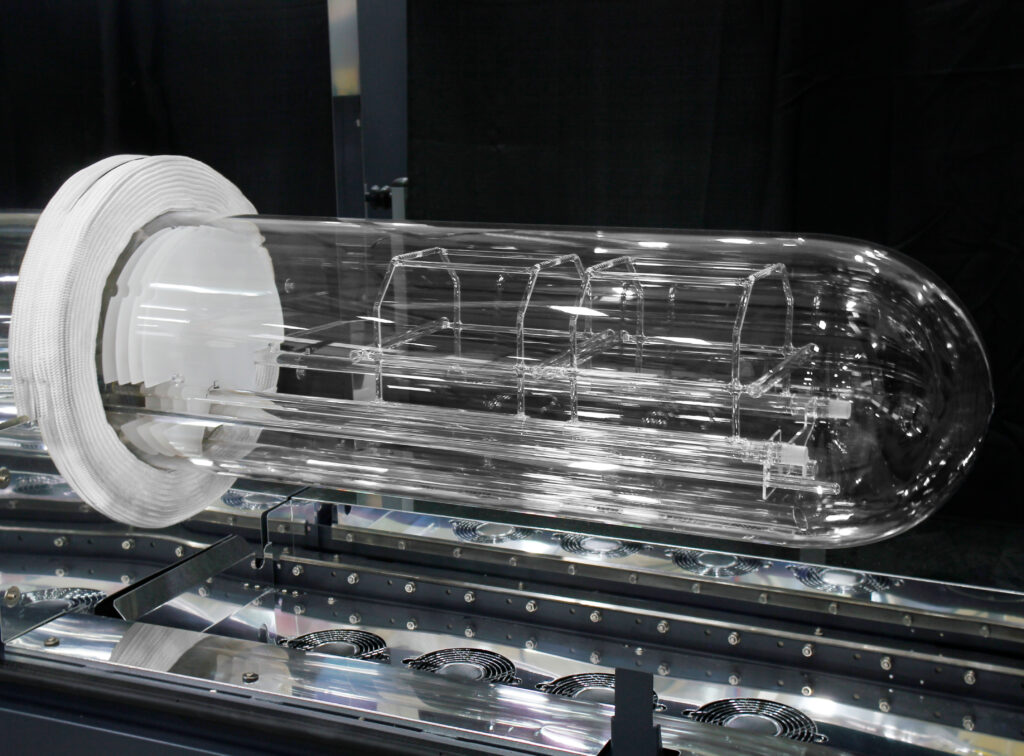

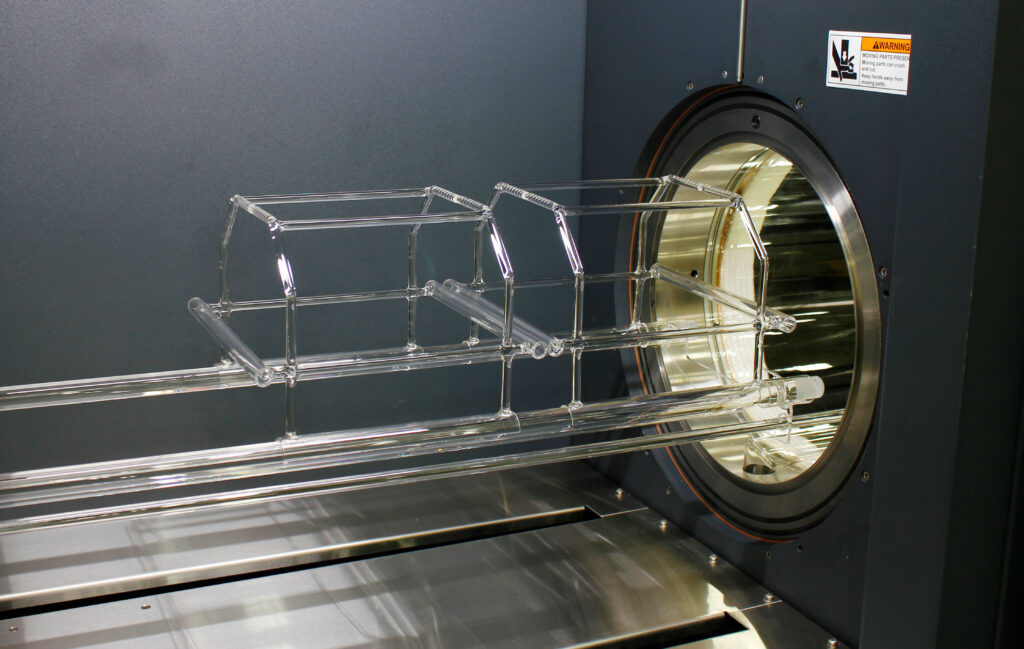

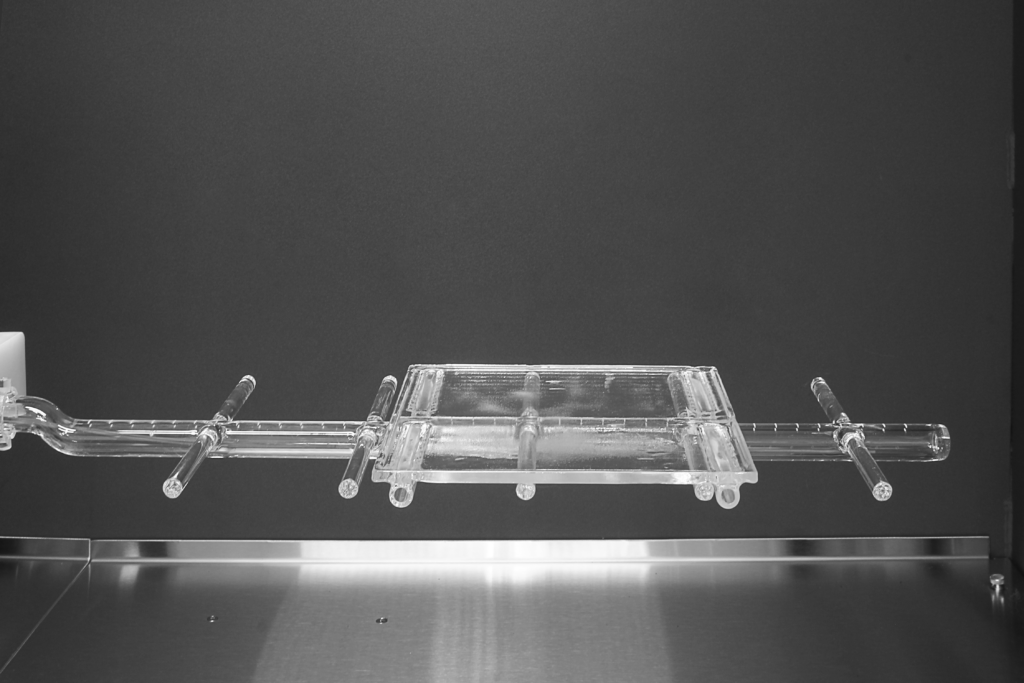

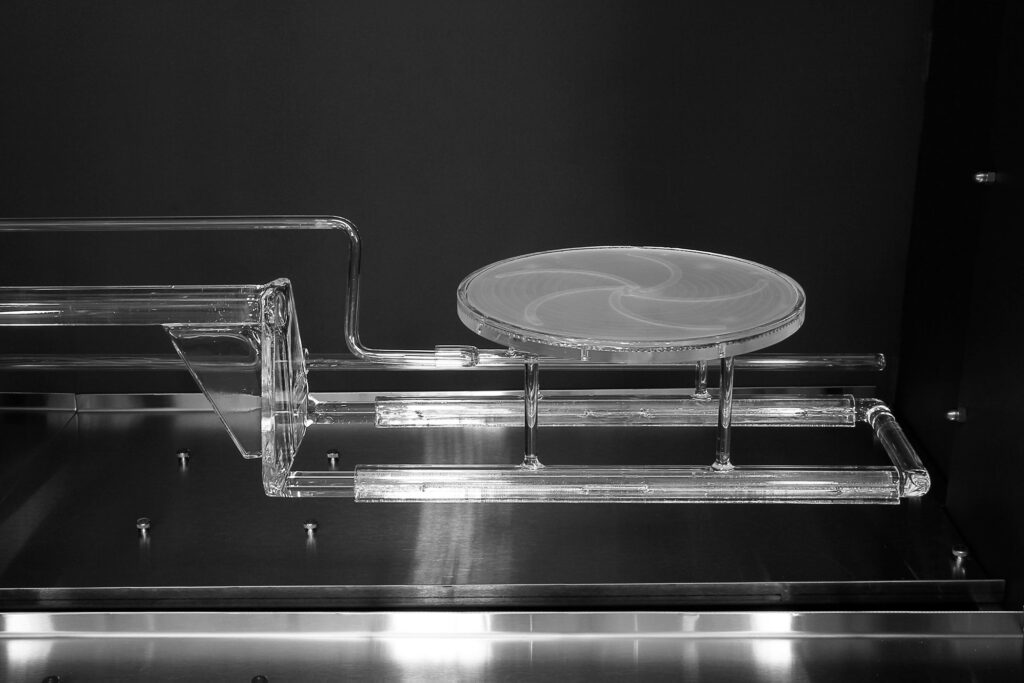

The base system includes a cylindrical quartz process tube which is configured for the required substrate size. A range of optional modules can be configured to meet the specific requirements of the end user. Many of the options are available as upgrades after installation.

The FirstNano product line is designed to meet today’s safety standards for handling pyrophoric, corrosive, flammable, and toxic gases such as hydrogen, hydrocarbon gases, silane, germane, diborane, hydrogen chloride, and metal-organic precursors.

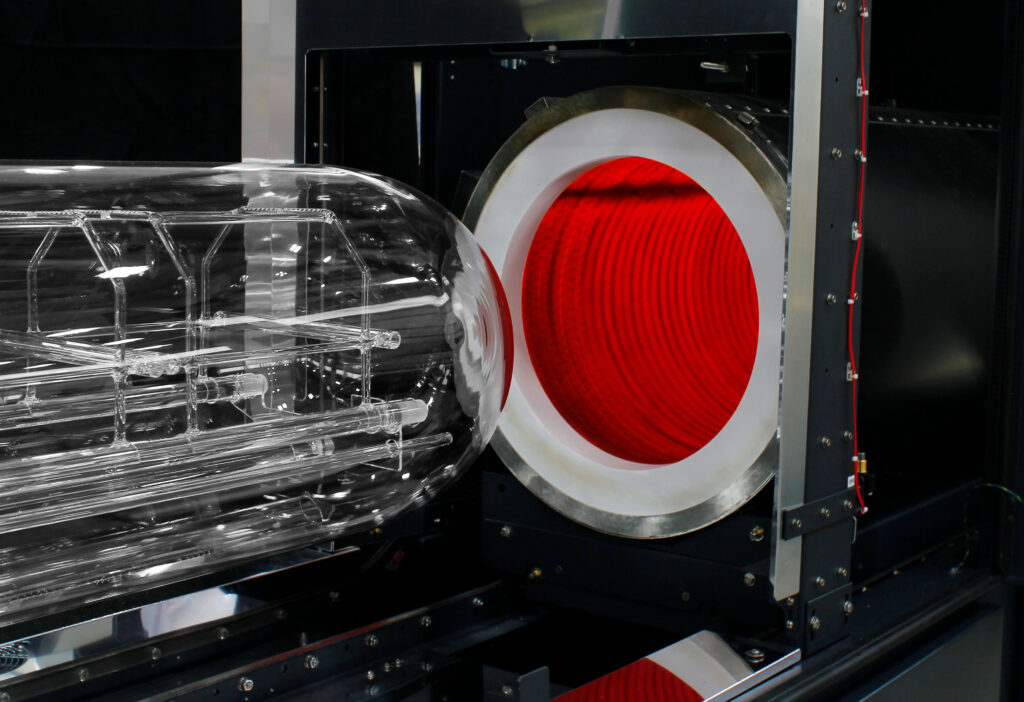

The Carbon+ systems have an optional extended frame size to accommodate larger substrates and system options. These options include a glovebox, load lock, a rolling furnace for rapid heating and cooling, and an upstream RF plasma generator. The Carbon+ system can accommodate up to full 6” diameter wafers, larger substrate sizes are available upon request.

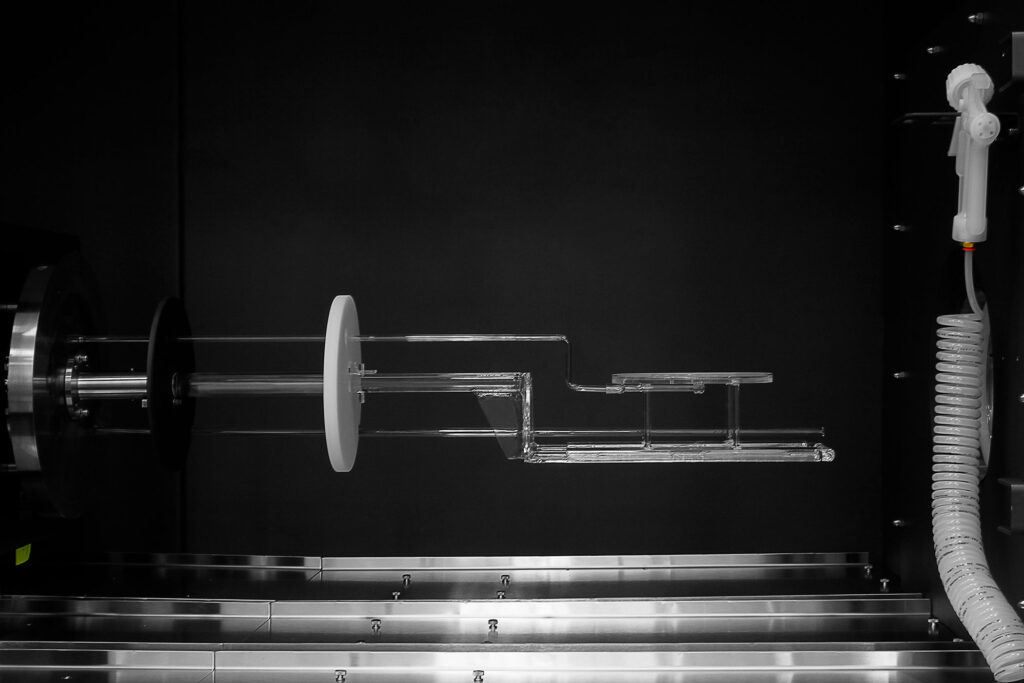

Rolling Furnace

Fast heating and cooling

6-Zone Resistance Furnace

Resistance heating to 800°C

Comprehensive safety system

CVDWinPrC™ system control software

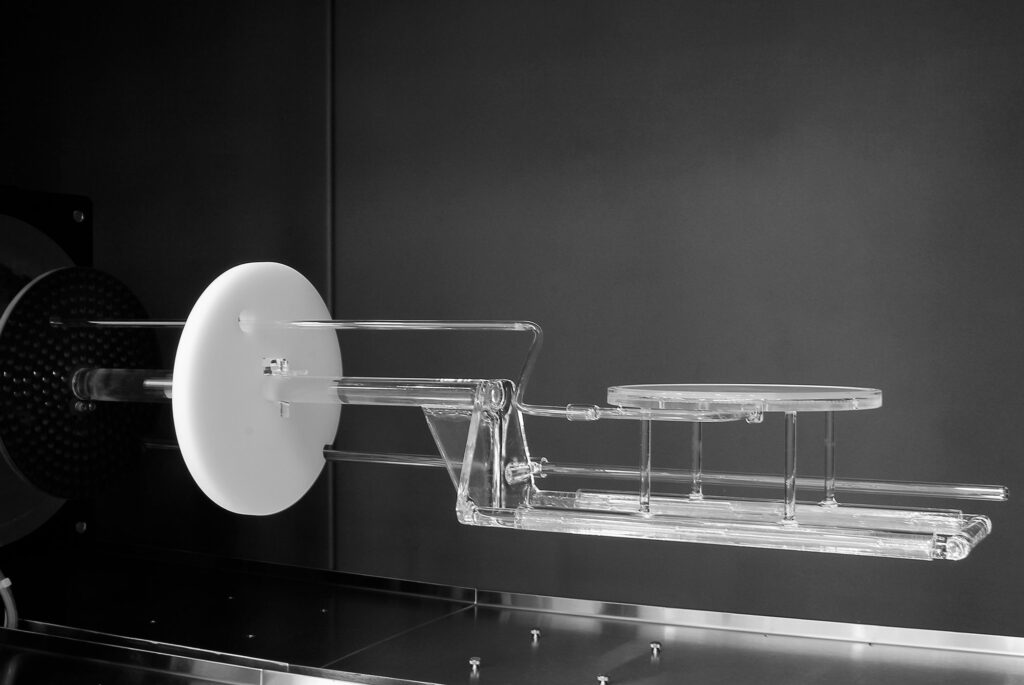

Increased Capacity

Foil substrates hung vertically

Carbon+™ 300 Features & Benefits:

Production of high-quality Carbon Nanomaterials including CNTs

6-zone resistance heating to 800°C

Rolling furnace for fast heating and cooling

Integrated burn box for gas abatement

14-inch (350mm) diameter quartz tube

Sample fixturing enables up to 32 pcs of 8-inch x 8-inch foil substrates

Pilot production of CNTs on foil substrates

The CARBON+300™ system is engineered for the pilot production of high-quality carbon nanomaterials and composite structures. It includes an integrated package of gas delivery, CVD processing, and exhaust byproduct management.

CVD Equipment Corporation has developed process recipes to produce CNTs on foil substrates through its in-house Applications Laboratory. Our customers manufacture CNTs and other carbon nanomaterials in production for applications ranging from consumer products to advanced energy storage solutions.

Carbon+™ 300 Brochure

Production of high-quality Carbon Nanomaterials including CNTs

Carbon+™ 150 Features & Benefits:

Physical Vapor Transport (PVT) systems for the growth of 150 & 200+ mm diameter single crystal boules

SiC Crystal Growth & Annealing

High Temperature, RF Induction Heating up to 2500°C

Motorized Pyrometer Alignment via Remote Control Box for real-time monitoring of crystal growth

Vacuum System with Atmospheric Bypass

Safety System: PLC, PC, and Relay Safety Systems

Manufacturing Enterprise System (MES) Compatible Integration

CVDWinPrC™ system control software for real-time process control, graphing, data logging, and process recipe editing

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”