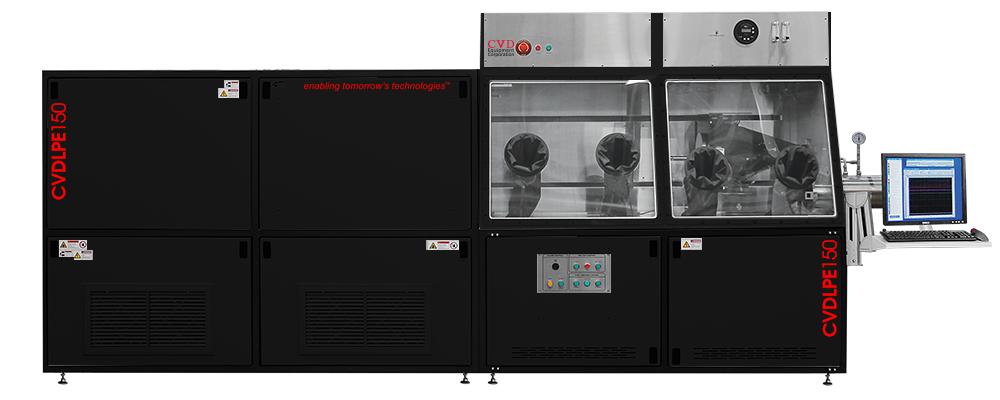

LPE Reactor System

Liquid Phase Epitaxy (LPE) Systems

Our LPE systems provide the user with a process-controlled furnace for automated user-specified segment-driven process recipes that achieve optimum control over wafer processing and repetitive results from run to run. The overall systems are designed to reliably grow epitaxial layers of semiconductor materials including mercury cadmium telluride (MCT, HgCdTe) and Gallium Arsenide (GaAs). The LPE systems are capable of processing a wafer over a uniform flat temperature zone.

Multi-zone Rolling Furnace

Temperatures up to 700 °C

Load Lock

Evacuated to 10-6 Torr and pressurized to 200 PSIG

Glove Box

Unloading Sample Under Inert Ambient Conditions

CVDWinPrC™ Software

Real-time process control, data logging, and recipe editing

An automatic, cantilevered, non-contact wafer loading system is incorporated for the loading and unloading of the graphite process boat. The loading system consists of a quartz boat holder that is cantilevered from the automatic end cap assembly. The end cap assembly locates the process boat within the quartz condensation sleeve inside the quartz process tube. The translation speed of the loading system is adjustable from 50-300 mm/min. Door interlocks are provided to prevent the startup of a process run in the event of an incomplete door closure.

CVD Equipment Corporation also offers a vertical dipping system for LPE growth of thicker films at higher rates. It operates at pressures up to 200 PSIG and temperatures up to 700°C. The system has a transfer chamber that can be evacuated to <10-5 Torr and pressurized to 200 PSIG.

LPECVD SYSTEM FEATURES & OPTIONS

Multi-zone rolling resistance furnace for temperatures up to 700°C

+/- 0.25°C temperature uniformity over the flat zone

Rapid controlled heat-up and cool-down of LPE boat

Automatic boat slider

Comprehensive software and hardware safety interlocks

Nitrogen Purged Glovebox with antechamber for moving parts in and out

Integrated vacuum system to 10-6 Torr

User settable warnings and alarms

CVDWinPrC™ system control software for real-time process control, graphing, data logging, and process recipe editing

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”