PECVD Systems

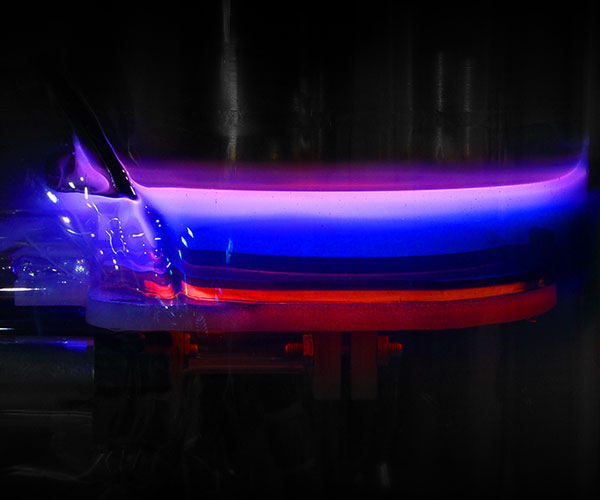

High-Performance Plasma Enhanced Chemical Vapor Deposition System for Thin Film Deposition & the Growth of CNFs & CNTs

Industrial Processes for the Semiconductor Industry

DC, Pulsed DC, or RF Plasma

Generating Layers of Nanomaterials Including CNFs & CNTs

Automated Showerhead Gas Delivery

Uniform Process Gas Distribution

Low Temperature Plasma Enhanced Technology

Uniform Growth on 200 mm wafers

Automated Wafer Loading and Unloading

Available with CVD Equipment Corporation’s Front-End Loader

The system is designed for PECVD processes for thin film deposition as well as growth of Carbon Nanofibers (CNFs) and Carbon Nanotubes (CNTs). Using low temperature plasma enhanced technology, reduced pressure, heat, and process gas delivery to the process chamber, the PECVD200™ offers excellent material property control, conformity, and step coverage. This solution provides enhanced temperature stabilization engineered for uniform growth across 200 mm wafers. The PECVD200™ is ideal for depositing semiconducting and dielectric films including thin SiO2 films for power electronics, other gate dielectrics, and nanomaterials, it can also be configured for graphene.

PECVD200™ Features & Benefits:

Available with CVD Equipment Corporation’s Front-End Loader for Automated Wafer Loading and Unloading

Wafer Temperatures Under Plasma Conditions up to 800 °C

Substrate Rotation up to 60 RPM for Increased Deposition Uniformity

Proprietary Multi-Zone Temperature Control System

Radial Center to Edge Temperature Uniformity of ±1% of Setpoint Temperature

Automated Showerhead Gas Delivery for Uniform Process Gas Distribution

Showerhead Temperature Control at up to 70 °C

Powered by our CVDWinPrC™ Process Control Software, for Real Time Process Control, Graphing, Data Logging, and Process Recipe Editing

In-Situ Plasma Chamber Cleaning

Compact Foot Print

Compatible with Industry Standard SEMI/MESC and SECS/GEM Cluster Tools

FEL200™ Features & Benefits:

Wafer Automation with High Throughput and Reliable Wafer Loading and Unloading

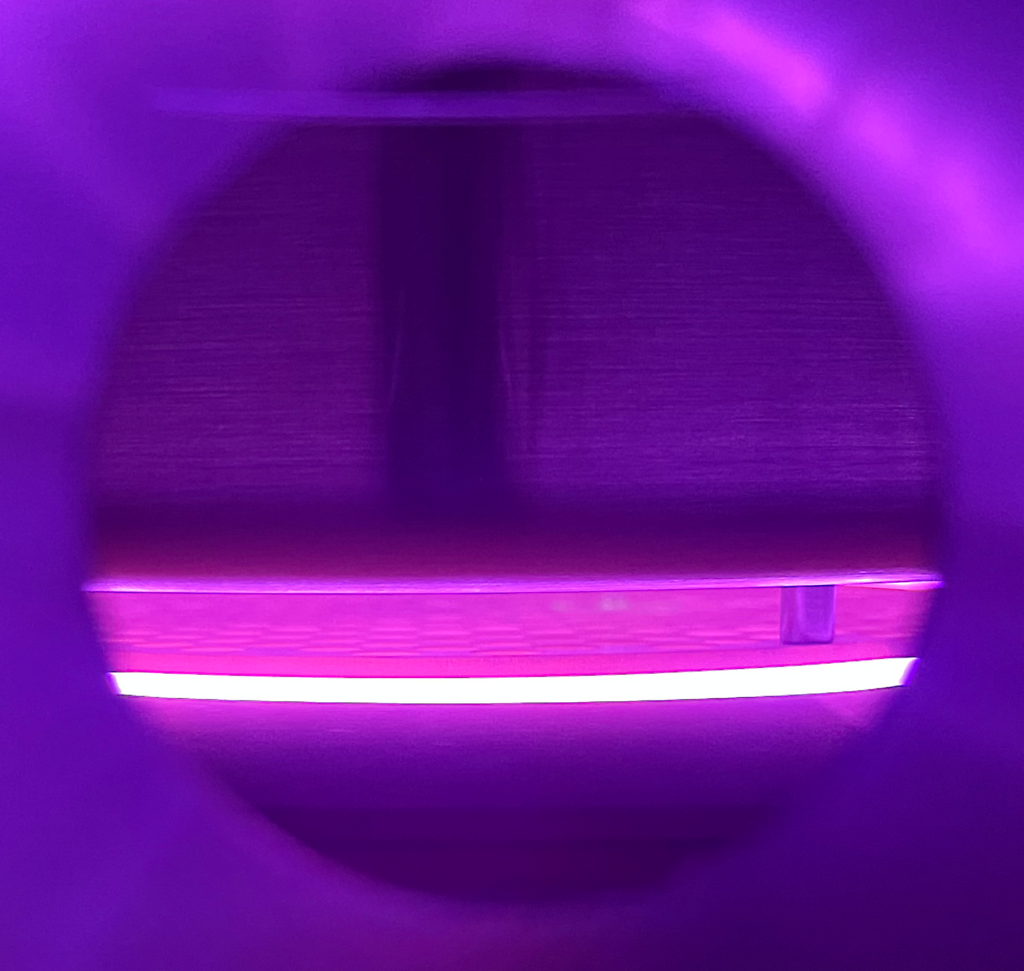

Side-Load Cassette Station with View-port

Metal Cassette Option for Hot Wafer Loading and Unloading

Cassette Platform Detection Sensors for Sensing both Opaque and Transparent Wafers, as Thin as 400 μm

Index Elevator with Wafer Mapping, used to Detect the Number of Wafers in the Cassette

Alignment Sensors to Ensure a Process Run Begins After Wafers are Centered and Aligned Properly, Alerting Misalignment

Optical Wafer Detection and Safety End Stops Which Signal the Motion System

Linear Transfer Arm with End Effector

Custom End Effectors are Available with Materials and Geometries to Meet Specific Application Needs

The FEL 200™ is a 25-Wafer Linear Transfer System that can accommodate 100, 150, and 200 mm wafers. The Front End Loader is designed to accept individual wafers or a cassette of wafers for single wafer transfer and processing under vacuum.

The FEL 200™ is compatible with CVD Equipment Corporation’s Process Modules and is MES compatible. Our proprietary Front-End Loader can accept individual wafers or a cassette of wafers and includes a dedicated pumping and purging system that can achieve pressures as low as 5 x 10-5 Torr.

PECVD200™ Brochure

View our PECVD200™ Spec Sheet with Technical Data

We also offer EasyTube® systems through our FirstNano® brand of R&D products for CNT and graphene growth at lower temperatures using inductively coupled plasma.

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”