PowderCoat 300™

R&D Systems for Uniform Powder Coating and Infiltration

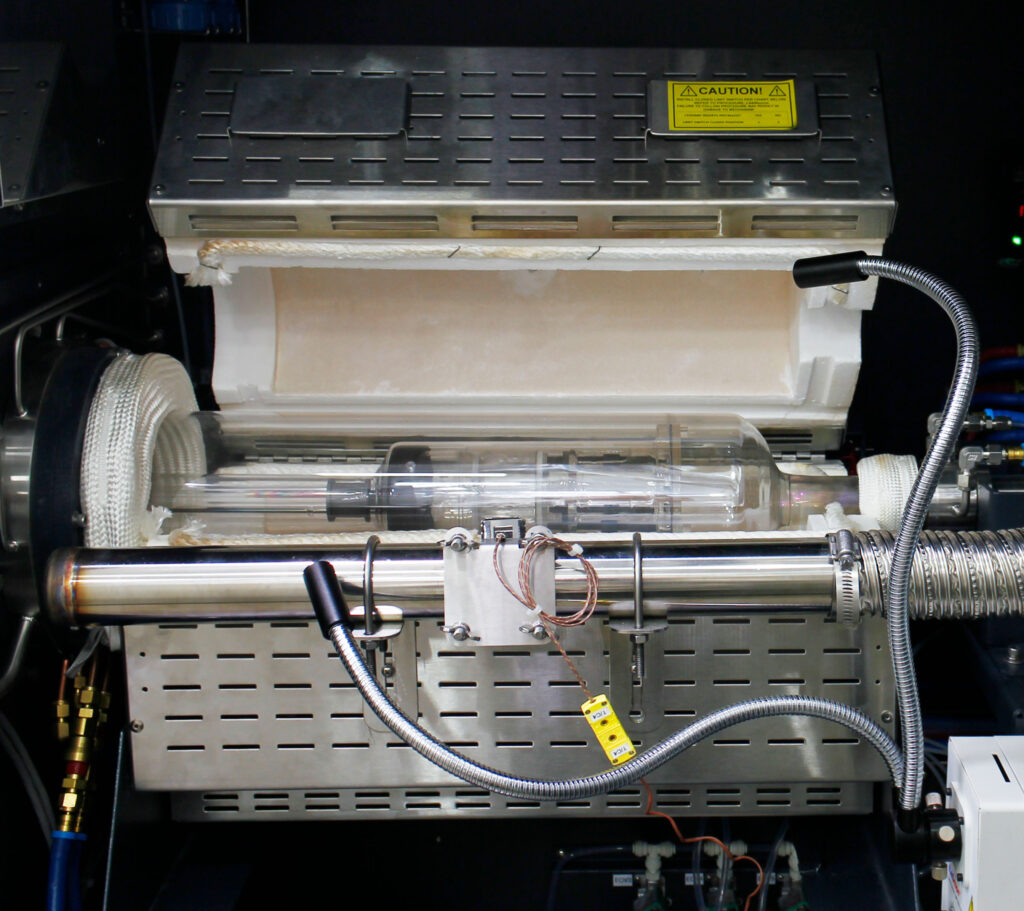

The PowderCoat 300™ is a Chemical Vapor Deposition and Infiltration System designed to process powder materials for high-technology applications.

Three-Zone Resistance Furnace Heater

Clamshell heater with automatic opening and heat exhaust plenum for fast cooldown

Rotating Tumbler

Single-Chamber Reactor with Tumbler Design for Uniform Mixing

Glove Box

Unloading Sample Under Inert Ambient Conditions

Control Cabinet

Main control station WinPrC process control and graphing software

In this process, precursor gases react to form a coating onto powder substrates. Source gases are supplied through a gas management system to the inlet of a heated chamber. Thermodynamics and kinetics drive both precursor reaction and decomposition. A three-zone furnace with resistive heating can maintain process temperatures up to 1100°C. The chamber has a rotating barrel that mixes the powder during processing. Ramp up and ramp down rates are achieved by real time PID precision control. Our robust process control system maintains temperatures within half a degree as well as the pressure within +/- 1% of set point throughout deposition runs. Controlled and rapid cooldown features result in consistent processing and reduced cycle time.

Hazardous gas storage and delivery, process reactor, and exhaust treatment subsystems can be provided as a complete integrated solution. Each component of the System is taken from our expansive library of process equipment configurations.

PowderCoat 300™ Brochure

View our PowderCoat 300™ Spec Sheet with Technical Data

PowderCoat 300™ Features & Benefits:

Powder Infiltration & Uniform Coating

Single Reactor Chamber Processing

Low-Pressure CVD

3 Zone Resistance Furnace Heating Systems

Customizable Reaction Chamber

Rotating Tumbler for Uniform Mixing

Robust Production System with Enhanced Process Controls

– Temperature Control +/- 0.5°C

– Pressure Control +/- 1%

Rapid Cool Down

Glovebox for Unloading Sample Under Inert Ambient Conditions

CVDWinPrC™ system control software for real-time process control, graphing, data logging, and process recipe editing

powered by CVDWinPrC™

Powered by our CVDWinPrC™ process control software, the systems automatically log data and graphically show time-dependent values of user-selected parameters. CVDWinPrC™ also allows users to load preprogrammed recipes, modify, check, and create new recipes, and view real-time or saved process data.

Safety Protocols

The systems have application configured safety protocols embedded into relay logic, PLC, and CVDWinPrC™ software.

High-Touch Customer Service, Including:

- Site Survey

- Installation Coordination and Field Acceptance

- NRTL/UL/CE Certification Available

- Initial Start-Up Support

- On-Site Training

- Warranty Response and Remote Capability

- Help Desk Support & Customized Service Contract Plans

- Continuous Improvement Programs and Support

- Customized Site Support Contracts

- Spares and Consumables

- Preventative Maintenance

- Site Personnel Contracts

About Us

Over 40 years of expertise in CVD and thermal process equipment design and manufacturing.

“enabling tomorrow’s technologies ™ ”